Solutions

S06 Glass Panel

2、支撑跨度大,产品装烧灵活,适应性广

3、窑具整体重量轻,能耗低

4、适合于大型梭式窑

S06 Glass Panel

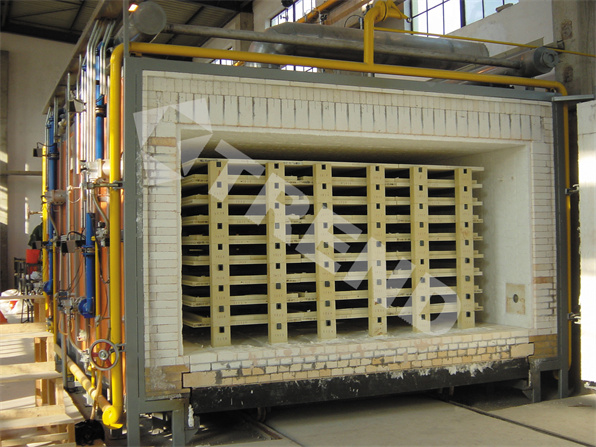

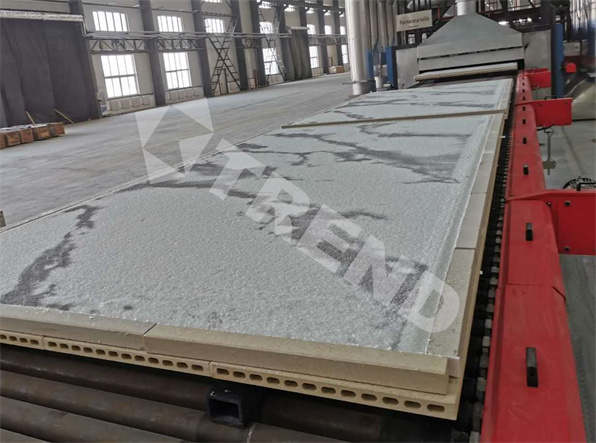

Glass panel (also known as glass stone) is a kind of artificial stone. Compared with natural stone, it has a series of advantages such as no radioactive contamination, good acid and alkali corrosion resistance, high strength, and minimal colour variation. Moreover, its raw material reserves are abundant, it is a new type of green and environmentally friendly building material with broad development prospects. The production process of glass panel is as follows: selected quartz sand, fluxing raw materials, and colouring materials are added to the melting furnace for melting, and frit is made after water quenching. The frit is put on the cordierite-mullite base batt, and then put the batt into the crystallizing kiln for crystallizing treatment at certain temperature (glass crystallizes into a microcrystalline state), and after taking out of the kiln, it is cut and polished like marble to obtain the final product. The crystallizing treatment of glass panel can be carried out in tunnel kiln, shuttle kiln and roller kiln. The fuel must be clean fuel such as natural gas, liquefied petroleum gas, city gas or producer gas, light diesel oil, etc. The crystallizing temperature is generally at 1120-1150°C, the crystallizing time (i.e. firing time) varies in different types of kilns, generally 12-24 hours in tunnel kilns, 8-20 hours in shuttle kilns, and 4-12 hours in roller kilns.

Since its establishment in 1998, Trend has started to study the most critical kiln furniture for the crystallizing firing of glass panel – extruded batts. Trend put extruded batts into industrial production in June 1999. Trend has made important contributions to the development of glass panel industry of China. At present, Trend has become one of the world leaders in kiln furniture for glass panel both in terms of quality and sales volume.

The kiln furniture system for glass panel includes batts (extruded batts, plain batts), base batts (for roller kilns), silicon carbide beams, support bricks, bases of support bricks, retaining bars, etc. In order to promote the production technology of thin batts for glass panel and its roller kiln firing, Trend has successfully developed ultra-thin large extruded batts and base batts, which helps with further reduction of the fuel consumption of glass panel. Based on rich experience in kiln furniture structure design, production, use and after-sales service for glass panel, Trend can also provide special kiln furniture solutions for special glass panels (glass ceramics).

Main Products Used

Download of Related Product Catalogue

Copyright © 2023 Tianjin Trend Thermal Materials Co., Ltd 津ICP备2021009632号-1