Solutions

S09 Powder Metallurgy

2、支撑跨度大,产品装烧灵活,适应性广

3、窑具整体重量轻,能耗低

4、适合于大型梭式窑

S09 Powder Metallurgy

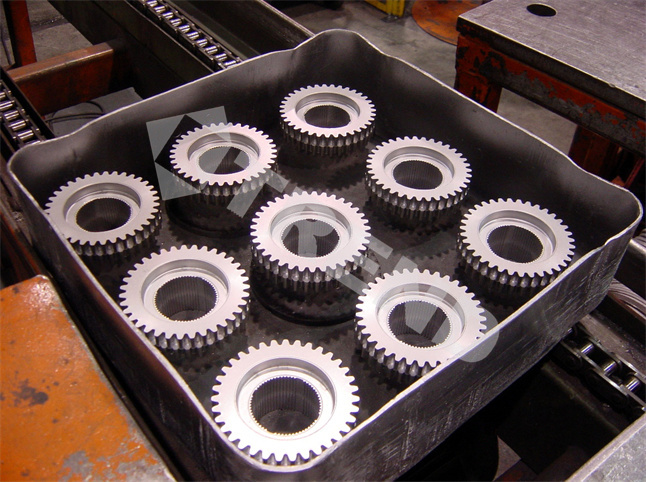

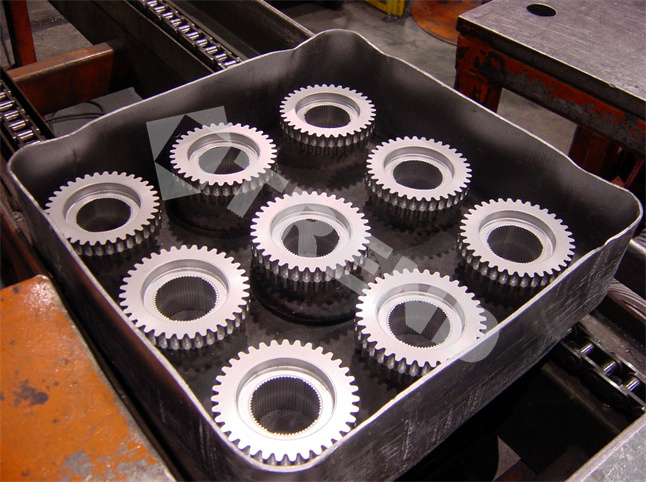

Powder metallurgy industry uses metal powder (or a mixture of metal powder and non-metal powder) as raw material, and manufactures mechanical parts by the moulding-sintering process. The pressed mechanical parts need to be sintered at certain temperature and atmosphere to obtain products with appropriate features. The sintering temperature varies depends on the type of metal powder. Generally speaking, the sintering temperature of iron-based parts is between 1050-1250 °C, and the sintering time is 20-30 minutes; the sintering temperature of copper-based parts is between 750-1050 °C, the sintering time is 15-30 minutes; for stainless steel and high-speed steel parts that require vacuum sintering, the sintering temperature is as high as 1250-1350°C, and the sintering time is about 60 minutes. Most powder metallurgy parts are sintered with protective atmosphere to prevent oxidation, reduction of metal oxides or addition of certain ingredient during sintering. Commonly used atmospheres include oxidizing atmosphere, reducing atmosphere, inert atmosphere or neutral atmosphere, carburizing atmosphere and nitriding atmosphere. The sintering atmosphere used is related to the material of the parts, and sometimes different sintering atmospheres are used in different sintering stages. Powder metallurgy sintering furnaces are generally heated by electric heating elements, which can be divided into two categories: continuous sintering furnaces and intermittent sintering furnaces. The former includes mesh belt sintering furnaces, beam pushing sintering furnaces and rod pushing sintering furnaces. The latter has a bell/beehive pressure sintering furnace, vacuum sintering furnace (vacuum carbon tube furnace, intermediate frequency induction furnace) and so on.

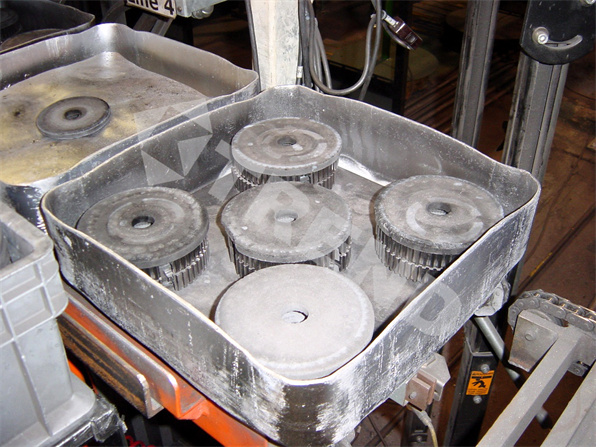

The temperature of kiln furniture used in sintering furnaces in the powder metallurgy industry is not too high (usually below 1280°C), but it needs to withstand severe rapid cooling to heating tests, and it is usually used in reducing atmosphere. Therefore, its kiln furniture material is different from the general cordierite-mullite material for ceramic industry. According to the special features of the powder metallurgy industry, two special cordierite-mullite materials, DOA and DOB were developed in cooperation with DYSON, United Kingdom, which have good thermal shock stability and can be used in oxidizing atmospheres, inert atmospheres and weak reducing atmospheres. Moreover, it does not stick with powder metallurgy parts during loading, but it cannot be used in the strong reducing atmosphere.

Main Products Used

Download of Related Product Catalogue

Copyright © 2023 Tianjin Trend Thermal Materials Co., Ltd 津ICP备2021009632号-1