Quality & Technology

Design and Material Guide

- Categories:Quality and Technology

- Time of issue:2021-12-01 17:48:24

- Views:0

In any high-temperature environment that needs to withstand thermal shock, the factors affecting the service life of products such as kiln furniture and kiln cars are very complex, not only related to the thermal shock resistance of materials, but also related to many factors such as product shape and system design.

Product Shape Design

● Minimise the product size as much as possible, while still satisfying the use;

● Make the product shape as simple as possible;

● Make the thickness of the product reasonable (thinner or thicker is not always better), and the thickness of the whole item should be as consistent as possible;

● When a certain area is thick, considering making it hollow;

● Avoid sharp corners on products by including a chamfering radius;

● Computer-aided simulation of the thermal stress distribution in a particular product can be used to optimize the product shape.

System Assembly Design

● Avoid fixed or rigid connections between products, try to use movable or flexible connections;

● Try to avoid using high-temperature cement to level or bond products. Use non-cohesive powder or flexible material to level the system when necessary;

● Turn over the batt in the system on a regular basis;

● Avoid the flame at the centre of burner from blowing the edge of batt directly, if not avoidable, add expansion gaps at the edges of batt or take other preventive measures;

● The assembled system should be conducive to the gas circulation in the kiln, try to ensure the temperature in the kiln or the same section is consistent;

● When it is not easy to place large pieces onto batt directly, cushion support should be used in between;

● When the size of assembled system is large, expansion gaps should be reserved at 3-4mm/m;

● When the temperature gradient of certain part is too large, the system should be assembled in decks, such as the side wall of the kiln car;

● Try to adopt interlocking design between products to ensure reliable and stable operation of large-scale system;

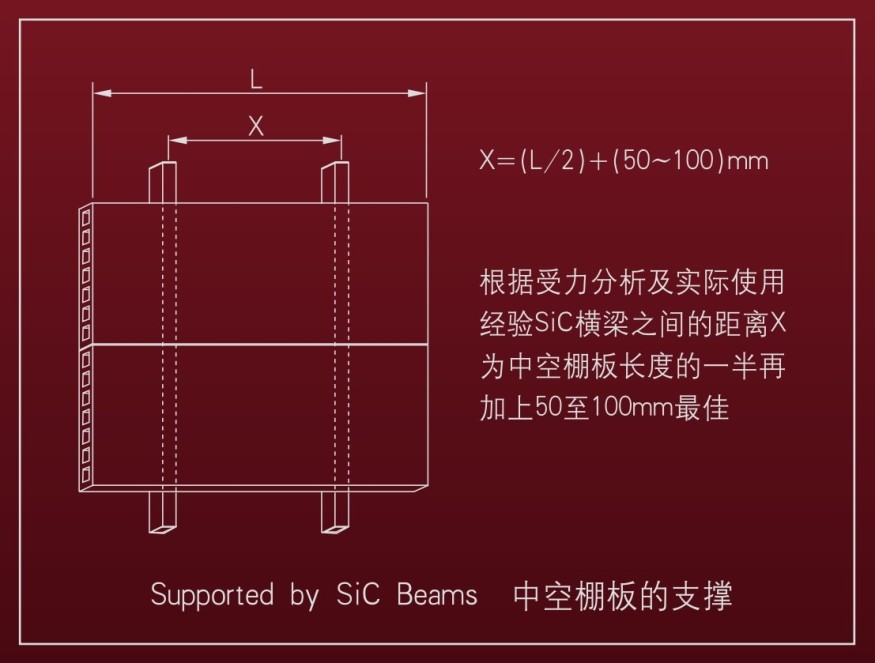

● Minimize the support span of thin products such as batts, try to distribute the load evenly on the support points;

● When building up a multi-deck system, ensure the support points among all decks line up with each other.

Material Selection

When selecting materials for a particular high temperature environment, the following factors should be considered:

● Type of fired products, main raw materials used, and volatile ingredients at high temperature;

● Type of kiln, main dimensions, maximum firing temperature, firing time, rapid-cooling zone (firing curve);

● Type, main impurity composition & content of fuel used for the kiln;

● The load and support method of the system;

● For existing kiln, evaluate existing materials and main breakage method.

For general customers, it is not easy to design product shapes in the assembled system and select the correct materials and recipes. Pre-sales service engineer is available to offer reasonable solutions.

Copyright © 2023 Tianjin Trend Thermal Materials Co., Ltd 津ICP备2021009632号-1