Solutions

S07 Foam Ceramics

2、支撑跨度大,产品装烧灵活,适应性广

3、窑具整体重量轻,能耗低

4、适合于大型梭式窑

S07 Foam Ceramics

Bubble ceramics is a type of foam ceramics, mainly referring to insulation boards of external wall, internal partition boards and non-load components in special shapes used in the construction field. It uses industrial and mining solid waste (slag, fly coal ash, fly ash, ceramic and glass waste, tailings of coal gangue and clay, granite, feldspar, etc.), shale, river and lake sludge, etc. as the main raw materials, added with vesicant, flux and stabilizer, etc. to make into powder materials by dry or wet mixing, and the materials are put in a mould cavity composed of cordierite-mullite kiln furniture. After about 10 hours firing at 1150-1200℃, the main and auxiliary materials melt and soften into high-viscosity melt under high temperature, and it chemically reacts with the vesicant to generate a large amount of volatile gas at the same time, resulting in overall expansion of the material. As the firing temperature decreases, the melt gradually solidifies and the pores formed by volatilization are preserved, and finally the lightweight ceramic material with dense closed pores with bulk density of 150-450 kg/m3, and thermal conductivity of only 0.05-0.15W/m∙K is obtained. It is then cut and machined into standard plates and components in special shapes. Foam ceramics have the features of light weight, high strength, good sound insulation & heat insulation performance, fire retardant, waterproof & moisture proof, mildew & antibacterial, strong weather resistance, acid & alkali corrosion resistance and easy processing, which are environmentally friendly and energy-saving building materials with good development prospects.

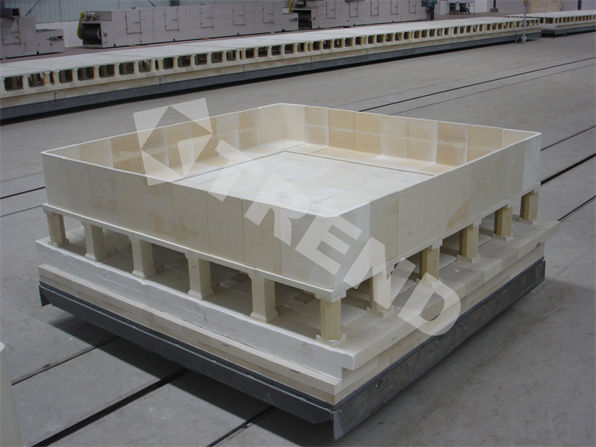

The domestic development of production technology of new foam ceramic building materials began at the end of the 20th century. At that time, Trend participated in it as a key material research unit and provided a complete set of kiln furniture for the first pilot production line. Later, Trend also successfully developed super-large & ultra-thin high thermal shock cordierite base batt and its application technology, which provided strong support for the rapid firing of foam ceramics on roller kiln. At present, the foam ceramic kiln furniture system from Trend has been very mature and has formed a series of products. We can provide single-deck, double-deck and multi-deck kiln furniture systems for tunnel kilns, roller kilns, and shuttle kilns. The kiln furniture system can work for production of foam ceramic plate with maximum size of 2400X2400mm.

Main Products Used

- T01 Base Batts

- T02 Extruded Batts

- T03 Plain Props

- T04 Extruded Props

- T05 Prop Accessories

- T11 Beams & Rollers

Download of Related Product Catalogue

General Refractory Kiln Furniture System

Copyright © 2023 Tianjin Trend Thermal Materials Co., Ltd 津ICP备2021009632号-1