Quality & Technology

Material Technical Properties

- Categories:Quality and Technology

- Time of issue:2022-03-11 11:59:35

- Views:0

Thermal shock resistance refers to the ability of high-temperature materials to resist damage caused by rapid changes in temperature. It is also called thermal shock stability, or rapid cold & hot resistance, etc, which is the combined performance of the material mechanical properties and thermal properties when subject to temperature changes. For kiln furniture, it directly affects its service life. The factors that affect the thermal shock resistance of high-temperature materials are very complex, mainly including the strength, fracture energy, elastic modulus, thermal expansion coefficient, thermal conductivity, and microstructure of the material.

Trend specializes in the research and production of materials with high thermal shock resistance that fall into four main categories: cordierite-mullite low-expansion materials, corundum-mullite high-temperature corrosion-resistant materials, silicon carbide high thermal conductivity materials, and fused silica micro-expansion materials, as well as some special functional materials. They each have their own characteristics which can meet the particular needs from different industrial fields, different high-temperature equipment and different applications. Trend is able to provide customers from different industries with complete and professional high-temperature material solutions.

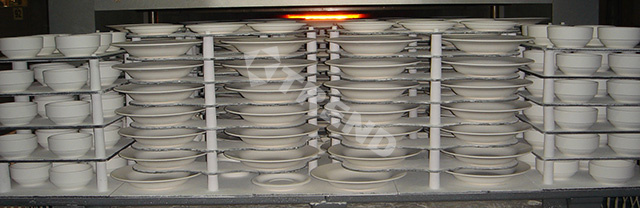

Cordierite-Mullite Materials

The composite material composed of cordierite (2MgO·2Al2O3·5SiO2), mullite (3Al2O3·2SiO2) and glass phase that makes full use of the characteristics of high temperature resistance of mullite and low expansion of cordierite. Its material characteristics mainly include low thermal expansion coefficient, excellent thermal shock resistance; suitable for various moulding methods and products of various shapes; suitable for most of the use requirements below 1350 ° C; relatively low material price; poor corrosion resistance, especially poor alkali corrosion resistance; not suitable for reducing atmosphere. Features of the main grades of Trend cordierite-mullite materials: RON and RAC are the most commonly used grades, with balanced high-temperature strength and thermal shock resistance, suitable for most applications; ROS has good creep resistance and thermal shock resistance, which is usually used for extruded props; LON is completely made of domestic raw materials, which is the low-cost RON. TEN, TED, TAQ, TAF and TUH series have good thermal shock stability. TEN and TED are easy to extrude, and are mainly used for extruded batts, roller bricks, perimeter blocks, etc.; TAQ is used for pressed batts; TAF is used for hand making products with complicated shapes; TUH is used for thick and heavy block products such as viaduct blocks and super large kiln parts, etc. DOA and DOB have better anti-deformation performance and slightly higher work temperature, but their thermal shock stability is slightly worse than the other recipes. EOY and EOG have better thermal shock stability (EOG has slightly better anti-deformation performance), and are usually used for kiln furniture for fast-firing kilns. NUA and NUK are used for cast complicated shapes or hollow products; GUA and GUP contain special additives, which can reduce glaze sticking and glaze erosion, and are usually used for secondary kiln furniture such as cranks, profiling rings and spacers for tableware ceramics. GAB, GAD, and GAF are special grades for the secondary kiln furniture system – cranks for glost firing. GOX, GOY, GOM and GOZ are all lightweight cordierite-mullite products, of which GOX and GOY are used for lightweight batts; GOM has better thermal shock resistance and is used for lightweight kiln furniture for fast-firing kilns; GOZ is used for dry-lock bricks for low heat storage kiln cars.

► Technical properties of cordierite-mullite products in recipes RON RAC ROS LON

► Technical properties of cordierite-mullite products in recipes DOA DOB

► Technical properties of cordierite-mullite cast products in recipes NUA NUK

► Technical properties of cordierite-mullite products in recipes GAB GAD GAF

► Technical properties of cordierite-mullite products in recipes TEN TED TAQ TAF TUH

► Technical properties of cordierite-mullite products in recipes EOY EOG

► Technical properties of cordierite-mullite products in recipes GUA GUP

► Technical properties of cordierite-mullite products in recipes GOX GOV GOZ GOM

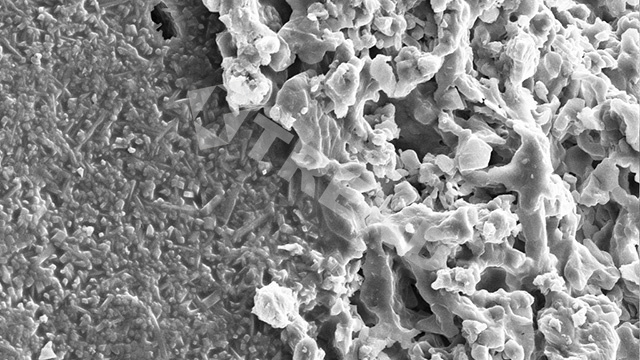

Corundum-Mullite Materials

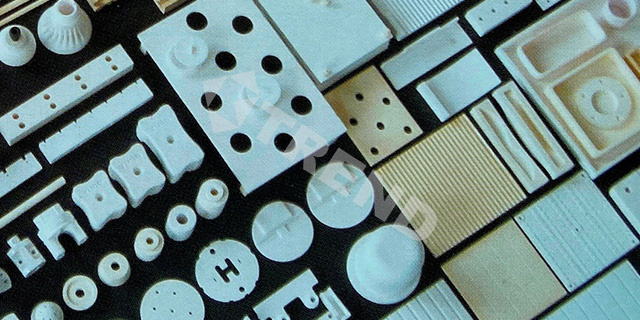

Both corundum and mullite are synthetic refractory materials. The corundum-mullite materials are composed by corundum, mullite, a small amount of glass phase and special additives. The components are mullite materials usually in long columnar shaped or needle shaped crystals, interspersing with each other in the product, forming a strong net shaped framework, wrapping up and connecting the corundum materials together. The characteristics of this kind of material are good creep resistance, high work temperature; strong corrosion resistance; good thermal shock resistance; suitable for various firing atmospheres; the highest work temperature is up to 1550 ° C; not easy to contaminate the fired products. Features of Trend main grades of corundum-mullite materials - ZCM is the most used corundum-mullite grade, which can be used to make high-temperature kiln furniture such as saggars, pusher batts, and loading batts. ZAB is a series of alumina bubble high-temperature lightweight products with different Al2O3 content, which are mainly used for high-temperature kiln linings. ALU95 and ALU99 are commonly referred as 95 porcelain and 99 porcelain, which are used to make high-temperature precision components.

Fused Silica Materials

Fused silica is a high-grade refractory raw material, which is usually made by melting pure silica sand in an electric arc furnace or a resistance furnace. The content of SiO2 is over 99.5% and the coefficient of thermal expansion is extremely low (0.54X10-6C-1,0-1000° C). This kind of material is made of fused silica and a variety of other materials. Its main features are low expansion coefficient, excellent thermal shock resistance; strong resistance to high temperature liquid erosion; suitable for various high temperature atmospheres; suitable for instantaneous extremely high temperature, but not suitable for above 1250° C of long-term firing. Features of Trend main grades containing fused silica materials - GEA is mainly used for the melting crucible for gold prospecting analysis (fire assay method), and its service life is 2-3 times that of ordinary crucibles. GHL is mainly used for the runner materials in contact with the superalloy melt in the investment casting process.

Silicon Carbide Materials

Silicon carbide has extremely high thermal conductivity but moderate thermal expansion, so silicon carbide products made of it usually have good thermal shock resistance. According to different binding phases, the most commonly used are silicate bonded silicon carbide products (OSiC), siliconized reaction sintered silicon carbide products (SSiC), nitride bonded silicon carbide products (NSiC) and recrystallized silicon carbide products (RSiC), they have both commonalities and characteristics. OSiC, the price is relatively the lowest, and the work temperature can reach 1500 ° C. It is not suitable for making large-scale products such as beams and rollers. SSiC, low price, extremely low porosity, strong oxidation resistance, low work temperature which is not exceeding 1350°C, can be moulded by casting or vacuum extrusion, suitable for making hollow products such as beams. NSiC, excellent thermal shock resistance, good oxidation resistance, moderate price, maximum work temperature 1450°C, suitable for products of any shapes. RSiC, the maximum work temperature can reach 1600°C, the anti-oxidation performance is average, and the price is relatively high. GMA, GMB, GMC and GMD are silicon carbide-containing materials for special purposes, all of which require casting. Among them, GMA is mainly used to make furnace linings and muffle plates with complicated shapes; GMB is used for linings of corrosion-resistant chemical pipelines; GMC and GMD are used for linings of chemical pipelines and special products that need both high temperature resistance and corrosion resistance.

Other Functional Materials

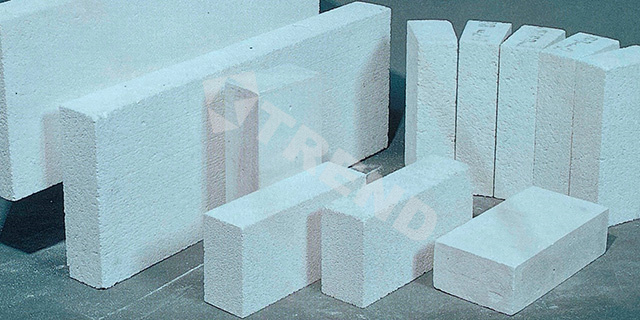

In addition to the above four categories of materials, Trend has also developed special functional materials for some emerging industrial fields: ZLC, ZLJ, ZLN and ZLM are for various saggars used to make calcined lithium battery cathode materials, which are highly resistant to alkali erosion and have long service life. In addition, to provide customers with extended services and comprehensive thermal solutions, Trend also provides general-purpose high-temperature materials: BJM and BMT are lightweight mullite brick series that can be used in general industrial kilns and refractory mortar for bricklaying series. FBC is the commonly used refractory fibre series, FBK is the refractory fibre blanket series, and FZB is the refractory fibre folding block series. These general-purpose high-temperature materials are produced by designated manufacturers in accordance with TREND technical standards and quality management system, and good quality assurance is provided by the manufacturer and TREND (Note: All those marked with green TREND+ in the technical performance chart of TREND materials are made by the designated manufacturers).

► Technical properties of lithium battery saggars in recipes ZLC+1 ZLJ+1 ZLM+1 ZLN+1

► Technical properties of refractory cements in recipes BJM26 BJM28 BJM33

► Technical properties of refractory fibre blankets in recipes FBK126 FBK140

► Technical properties of refractory fibre folding blocks in recipes FZB126 FZB140

► Technical properties of mullite lightweight bricks in recipes TJM23 TJM26 TJM28 TJM30 TJM32

► Technical properties of refractory fibres in recipes FBC126 FBC140

► Technical properties of refractory blankets in recipes FBK150 FBK160

► Technical properties of refractory fibre folding blocks in recipes FZB150 FZB160

Copyright © 2023 Tianjin Trend Thermal Materials Co., Ltd 津ICP备2021009632号-1