Solutions

S01 Low Mass Kiln Car

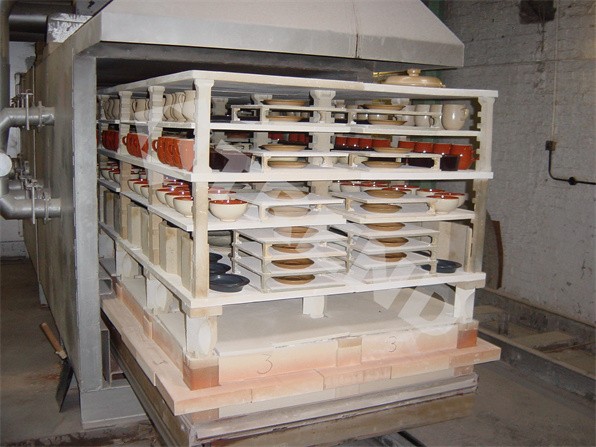

支撑跨度大,产品装烧灵活,适应性广

窑具整体重量轻,能耗低

适合于大型梭式窑

S01 Low Mass Kiln Car

Industrial kilns are generally composed of kiln body (kiln roof and kiln wall), kiln car base (the refractory materials below the base, roller kiln & pusher kiln, etc. do not have this item) and kiln furniture. The heat consumption of a kiln car base generally takes 15-50% of the total heat consumption of fired products. The base of the kiln car is subjected to frequent heating-cooling-heating cycles, and its overall weight should be light, which can reduce the heat storage during heating and shorten the cooling time during cooling, so that the fast firing can be achieved, and it is essential to reduce the fuel consumption of the kiln. At the same time, the thermal shock resistance of the base material is also very important, otherwise the kiln car base is easy to move, crack, and peel off, resulting in poor sealing between kiln cars, and between the kiln car and the kiln wall, which is easy for the heat to be transferred to the bottom of kiln car, not only causing fuel waste, also easily causing various serious problems such as deformation of the steel structure of the kiln car and damage to bearings, etc.

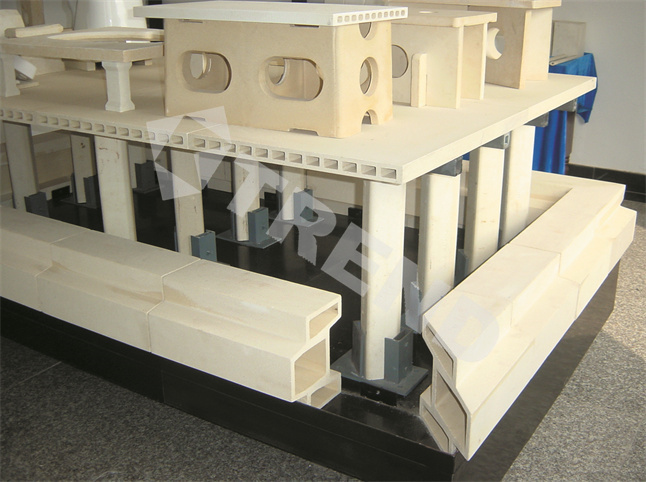

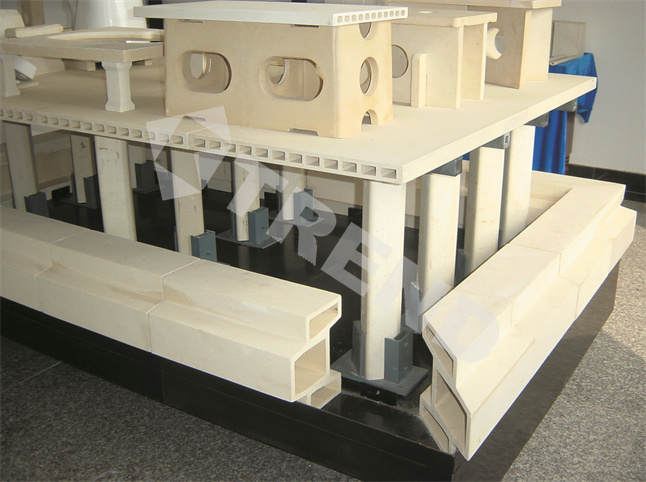

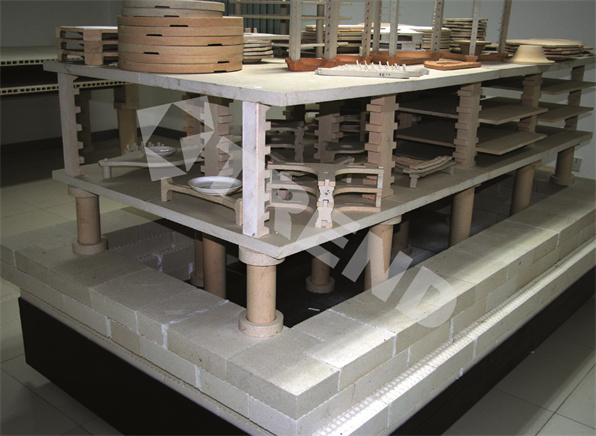

In order to meet the needs from different industries for low heat storage and high thermal shock kiln cars, Trend has designed and developed a variety of kiln car bases and supporting materials. Firstly, is to use the cordierite-mullite perimeter brick system, secondly is to use the high thermal shock dry-lock brick system, and thirdly is to use the cordierite-mullite thin batts inserted into the recessed props assembling into baffle kiln car. In addition, there are heavy-load kiln cars designed for brick and tile industries and special kiln cars designed for special firing atmospheres such as reducing atmosphere.

The kiln car of the perimeter block system uses perimeter bricks to form the surrounding walls of the kiln car, and the middle part is filled with light insulation materials such as refractory fibre blankets, etc., and the surface is covered with refractory batts; the outer edge of the perimeter bricks can be designed to the required shape to match the kiln wall seal, and the hollow part of the perimeter bricks is filled with refractory fibre. This kind of kiln car is light in weight, good in heat insulation, and no refractory cement used in between the perimeter blocks, so its overall thermal shock stability is good, service life is long, and can also work for fast firing process of the kilns. Its energy saving performance is very good, and it is suitable for various thermal kilns with light and medium loads. The kiln car of the dry-lock brick system is developed on the basis of the traditional light-weight refractory brick kiln car. Firstly, is to design the surface of dry-lock brick into convex and concave interlocking shapes, so that there is no need to use refractory cement for bonding around the kiln car, and a single dry-lock brick can expand and shrink freely; secondly is to update the material of the traditional lightweight brick. The dry-lock brick uses a specially developed cordierite-mullite lightweight material, which has a lower expansion coefficient and better high temperature creep resistance. Dry-lock bricks are as easy to cut and machine as the traditional lightweight bricks, and the kiln car can meet the curved sealing shapes of any kiln walls. After the four sides are built with dry-lock bricks, the middle part of the kiln car is also filled with lightweight insulation materials, and the surface is covered with refractory batts. The overall kiln car has excellent thermal shock resistance, almost no cracking, and a particularly long service life. It is also suitable for various types of light and medium load industrial kilns. Baffle kiln car is the lightest kiln car except for all-fibre kiln car (easy to cause bending problems and not easy to clean up due to fibre shrinkage, so it is rarely used). The cordierite-mullite thin batts are inserted into the props to form the four sides of the kiln car, and the middle box is filled with light insulation materials such as refractory fibre, and the top is covered with a thin batt. This kind of kiln car is especially suitable for fast firing kilns with light load and simple seal. The above three types of kiln cars are not suitable for heavy loads or reducing atmospheres.

Main Products Used

- T01 Base Batts

- T02 Extruded Batts

- T03 Plain Props

- T04 Extruded Props

- T10 Kiln Accessories

- T12 Insliation Materials

Download of Related Product Catalogue

Copyright © 2023 Tianjin Trend Thermal Materials Co., Ltd 津ICP备2021009632号-1