Solutions

S08 High Voltage Electric Porcelain

2、支撑跨度大,产品装烧灵活,适应性广

3、窑具整体重量轻,能耗低

4、适合于大型梭式窑

S08 High Voltage Electric Porcelain

High-voltage electric porcelain (also known as high-voltage insulators) are important parts for high-voltage power transmission & transformation lines. There are usually ordinary electric porcelain material and high-strength porcelain material (also divided into high-silicon electric porcelain material and alumina electric porcelain material). Ordinary electric porcelain is mainly made of feldspar porcelain, with quartz, feldspar, and clay used as the main raw materials. The fired body contains 10-20% quartz, 10-20% mullite, and the balance 60-80% is glass. High-silicon porcelain is a high-strength electric porcelain material obtained by adjusting the ratio of clay, feldspar and quartz on the basis of ordinary electric porcelain; in alumina electric porcelain materials, corundum replaces quartz to form the structure body of high elastic modulus, the thermal expansion coefficient and internal strain of the material are small, and the arc resistance performance is improved. In order to meet the needs on ultra-high voltage, high current and long-span power transmission, high-voltage electric porcelain materials have gradually changed to high-silicon electric porcelain and alumina electric porcelain materials in recent years. The firing temperature of high-voltage electric porcelain is generally between 1250-1320°C. With the research progress of green body porcelain and the needs on energy saving & consumption reduction, the firing temperature has a downward trend (1250-1280°C). The firing of high-voltage electric porcelain mainly uses tunnel kiln, shuttle kiln, and bell/beehive kiln as well. Due to the large size of electric porcelain products, the firing time is long, up to 65-75 hours. The high-voltage electric porcelain used to be fired with reducing flames in China, but with the change of porcelain materials, more and more manufacturers use oxidizing flames for firing.

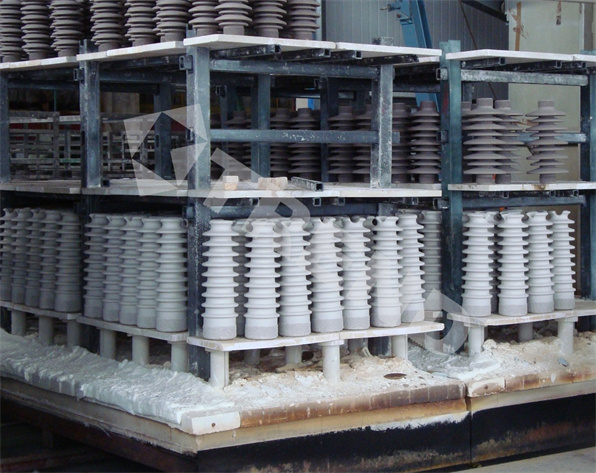

The kiln furniture used for firing of high-voltage electric porcelain products takes heavy load and soaks a long time at high temperature. In addition, most of them were fired with reducing flames in the past. Therefore, most of the kiln furniture is made of clay-bonded silicon carbide, oxide-bonded silicon carbide and recrystallized silicon carbide materials. In recent years, with the change of porcelain materials & firing atmosphere and the decrease of firing temperature, especially the great improvement of the performance of cordierite-mullite kiln furniture, more and more high-voltage electric porcelain manufacturers have used advanced combination of recrystallized silicon carbide and cordierite-mullite kiln furniture, which can fully play the high load advantage of recrystallized silicon carbide kiln furniture and long life, no dirt, and low cost advantages of cordierite-mullite kiln furniture. According to the special needs from the high-voltage electrical porcelain industry, Trend cooperated with DYSON, United Kingdom to develop RON (MON enhanced) and DOA cordierite-mullite materials in 2008. These two recipes are of high-temperature strength, strong bending resistance, and good thermal shock stability. Trend can provide full silicon carbide kiln furniture system (reducing flame firing), silicon carbide/cordierite-mullite kiln furniture system for tunnel kiln and shuttle kiln used in high voltage electric porcelain industry.

Main Products Used

- T01 Base Batts

- T02 Extruded Batts

- T03 Plain Props

- T04 Extruded Props

- T05 Prop Accessories

- T11 Beams & Rollers

Download of Related Product Catalogue

Copyright © 2023 Tianjin Trend Thermal Materials Co., Ltd 津ICP备2021009632号-1